Digitalization

From Mechatronics to Smart Data and Digitalization

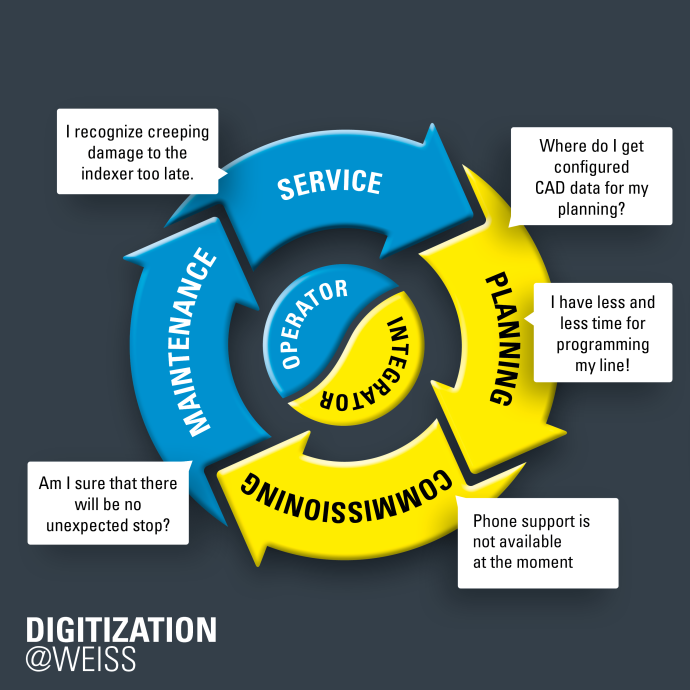

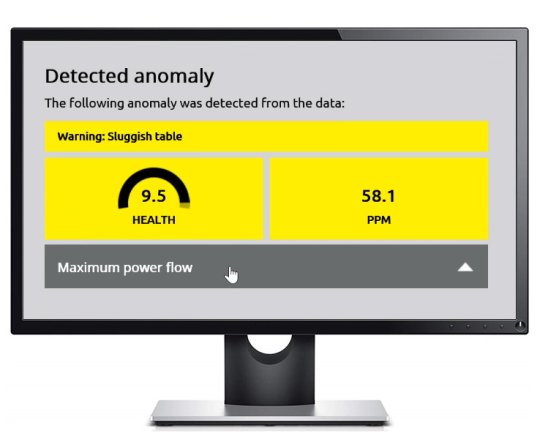

Innovations in sensor and actuator technology, in data transport and data storage, form the foundation for digitalization within and between companies. WEISS is aware of this and approaches digitalization in a structured way. In such a way that decisions can be made, learning processes can be initiated and instructions for operative processes can be obtained.

For WEISS, the aim is to generate mutual added value from the community of "man and machine". Machine and plant operators benefit from higher capacity utilization, more reliable use, higher and more reliable availability or flexibility in line with market requirements. Machine and plant manufacturers, in turn, gain more customer satisfaction, reduced storage costs or additional service revenue through the advantages gained by operators.

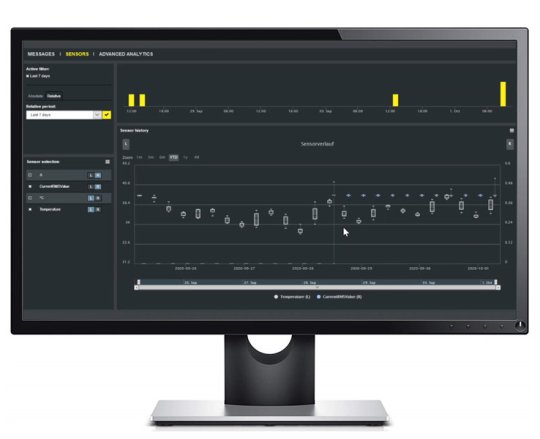

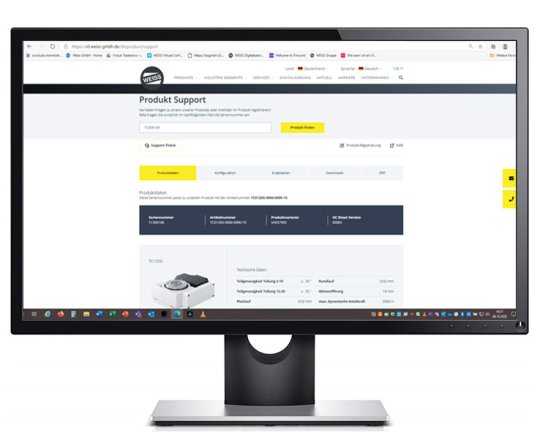

The introduction and use of modern digital technologies is therefore not an end in itself - rather a contribution to a sustainable approach to open system architecture, which makes digital engineering a central component. Weiss is involved as a pioneer for digital engineering, so that plant planning, commissioning, operation, maintenance and service of WEISS products can be easily integrated into customer systems and processes - including innovative evaluation and optimization methods. We develop and cultivate Smart Data: Uniform semantics, open interfaces, flexibility, intelligent services and adaptability to device, edge and cloud levels.

Digitization

Digitization

Digitization

Digitization

“I Wish I Had a Control Chain!”

I wish! What machine builders want is the ability to deploy appropriate control technology to configure motion so that it optimally supports the application at hand and works reliably.

read more » Digitization

Digitization

Towards digital engineering

We are in the year 2021. Mechanical engineering has initiated the digital transformation and the first paths towards digital engineering are being followed.

read more » Digitization

Digitization

Digitization at WEISS is a Matter of the Heads

Change starts with people. Marcel Nagel and Marijan Grandverger ensure more digitalization at the WEISS Group with their „digital responsibilities“.

read more » Digitization

Digitization

Digital Learning by Doing!

Do you know that the system integrator GLUTH Systemtechnik has clearly recognized the strategic importance of digitalization?

read more »Registered, tracked - hosted!

Many are already doing it and some have not yet recognized the added value: Tracking and tracing is a valuable quality orientation for manufacturing companies.

read more » Digitization

Digitization

Triple M: Digitalizing non-IT company areas

Digitalization goes hand in hand with various challenges. At the second Triple M-eeting in Stuttgart, Germany, the participants discussed how non-IT areas of companies can be introduced to digitalization topics.

read more » Digitization

Digitization

Triple M: Virtual commissioning as an independent discipline

Based on its experience in developing and using simulation software, ISG, the host of the 2nd Triple M, is very familiar with the challenges involved in applying these solutions.

read more » Digitization

Digitization

Triple M - Experience exchange in digitalization

With its “Triple M – Mission for medium-sized machine manufacturers” series, WEISS brings together machine manufacturing companies and software specialists in the area of simulation so that they can share their experiences.

read more » Digitization

Digitization

Triple M: Validating digital solutions in-house

At the second Triple M-eeting for exchanging experience, the focus was on discussing specific digitalization projects.

read more » Digitization

Digitization

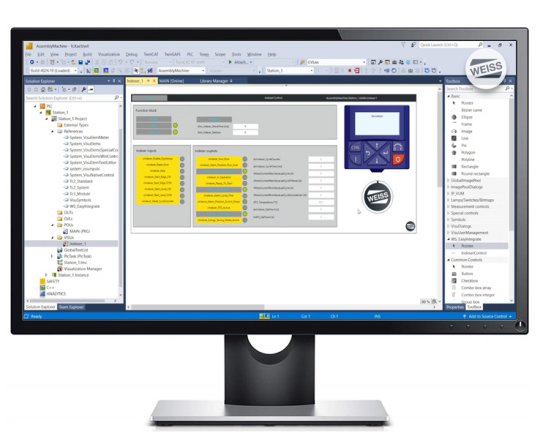

EasyIntegrate Libraries

Faster programming in the planning phase - Product libraries for your PLC

read more »