Battery and Fuel Cell

High-speed Components for Manufacturing Modules

The development of electric drive concepts has major impacts on production in the automotive industry. Most of all, the battery's design and placement in the vehicle are demanding a great deal from the flexibility and modularity of assembly systems in order to adapt the battery concepts to each type of vehicle. WEISS has been working closely with customers from the very beginning when the first pilot series concepts were created. Thanks to this wealth of experience, we have detailed knowledge of the processes and well-engineered automation components and subsystems for all battery manufacturing applications.

Typical Processes

- Winding electrode structures (jelly rolls) for prismatic or cylindrical cells

- Stacking and folding in the production of pouch cells

- Fixing in place and compressing jelly roll electrode stacks

- Inserting and welding electrodes into the case

- Installing the sealing cap

- Sealing the battery case by laser welding

- Filling cells with electrolyte, sealing and cleaning

- Combining single cells to make battery modules and packs

Application Examples

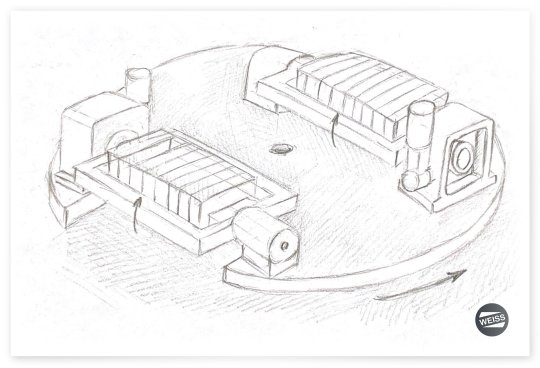

Positioning during Battery Module Assembly

Positioning of battery packs for connecting battery notching for hard case or pouch cells

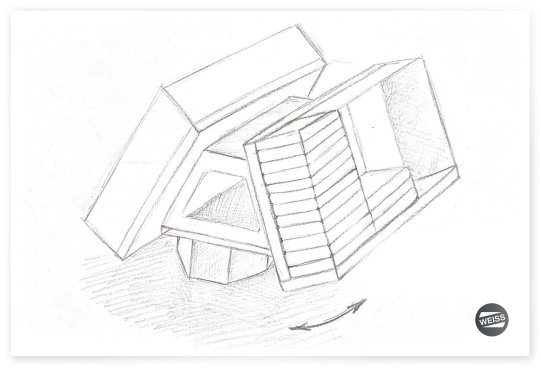

Battery Buffer Station

Buffer station for battery modules with heavy duty table CR500

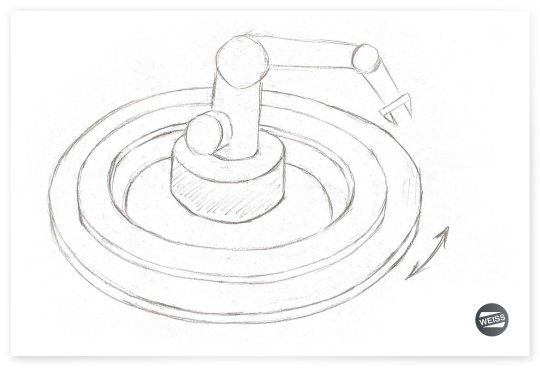

Final Assembly of Fuel Cells

Mount stacked stacks and provide with connections with ring indexing table NR