Machine Tools

Robust and Safe – Reliable Components in Single Machines

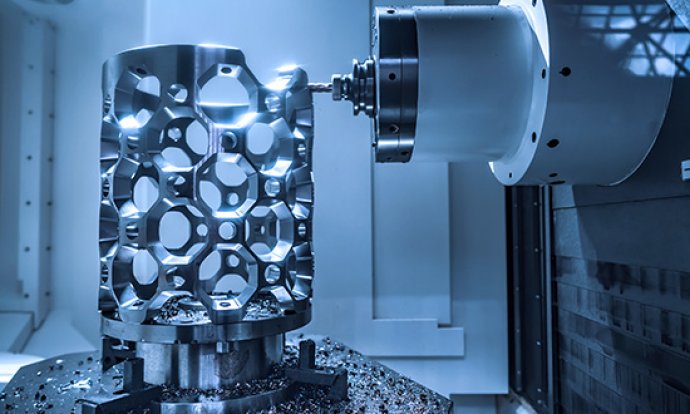

Turning, milling, drilling and grinding are some of the most important techniques for manufacturing machine tools. These techniques are fundamental for every manufacturing process and thus important motors for progress and innovation in the industry. The designs of machine tools range from simple CNC machines to machining centers and complex production lines. As the level of automation increases, the advantages of WEISS components become even more clear: precise and dynamic turning, moving and positioning, always with the goal of reducing costs and improving quality. Today, WEISS indexers are even used in the main axes of some machine series.

Typical Processes

- Handling workpieces during automated machine loading and unloading

- Tool changers with our shelf-version linear axes and our indexers as rotary magazines

- Pallet changers

- Torque-motor axes for medium machining forces in customized designs, e.g. for high-speed milling, grinding or laser cutting

- Indexers in electrical discharge machines (EDM)

Application Examples

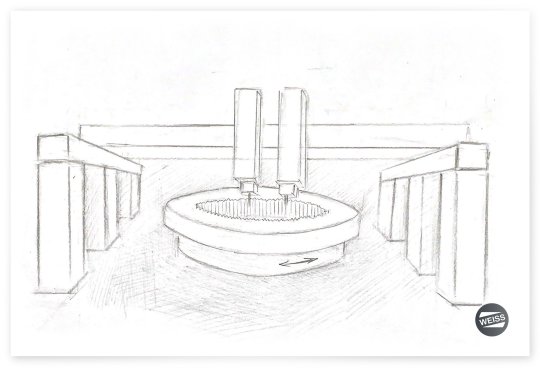

Hardening of Gear Wheels

Induction hardening system for very large gear wheels with heavy duty table CR2000

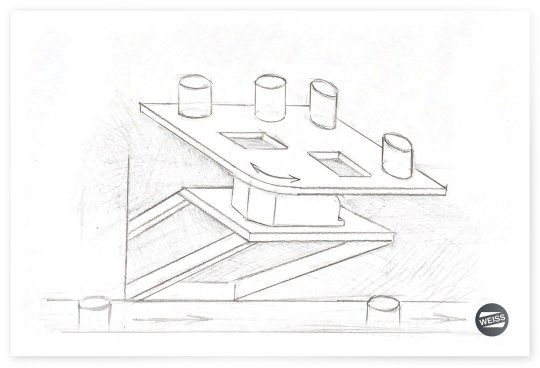

Workpiece Change in Machine Tool

Changing workpieces with rotary table TW