Sensors and Microswitches

High-precision Sensors with a Modular Design

The essential underlying basis for microswitches and modern sensors are MEMS (micro-electromechanical systems), tiny components that process mechanical and electrical information. These components make the use of electronic devices in the automotive, medical technology, safety and measurement technology and entertainment sectors considerably more versatile and intelligent. For several years, WEISS has been developing solutions that also operate in the nano-range. Using our modular automation system, we can scale the precision levels to match customer requirements and create cost-effective automation concepts that are based on standardized elements.

Typical Processes

- Producing and packaging sensors

- Assembling microswitches with Pick & Place systems and an indexer

- Aligning lenses for cameras in autonomous driving

- Endurance tests of microswitches for quality assurance

Application Examples

Depaneling of Printed Circuit Boards

Axis system with linear motor axes HN on granite for laser cutting of printed circuit boards

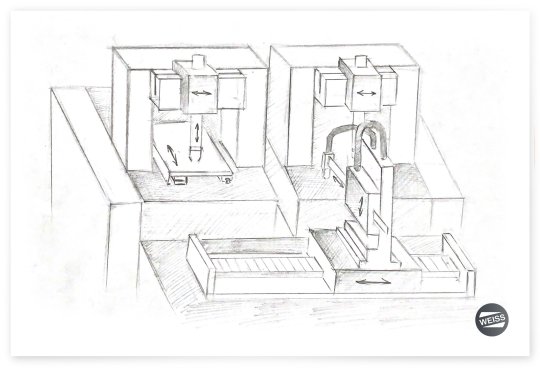

Assembly of microswitches

Automatic assembly machine for electromechanical sensors with HP70 and HP140 pick&place modules

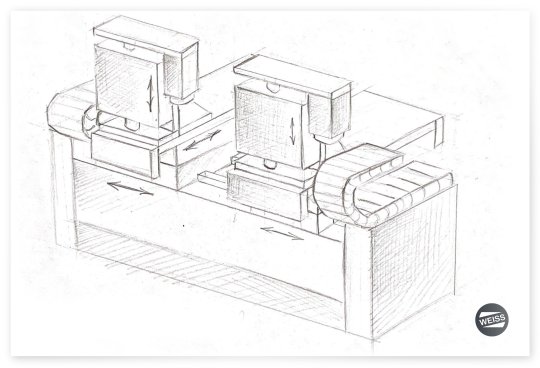

Production of Blood Sensors

Dispensing of microdroplets maintaining an accuracy of a few µm using a precision linear system on a granite base