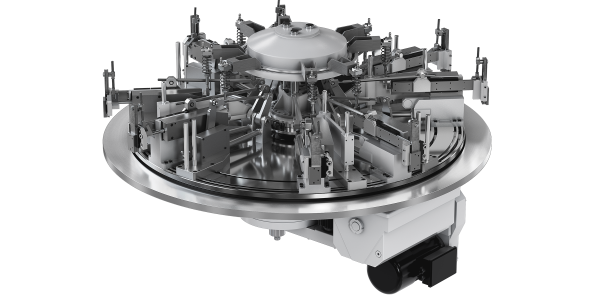

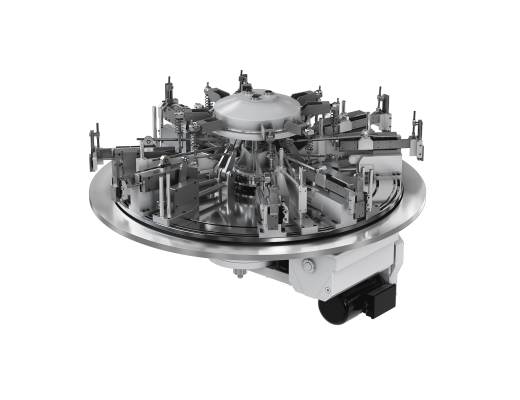

Pick-o-Mat (PM) Assembly Machine

Powerful and cost-effective

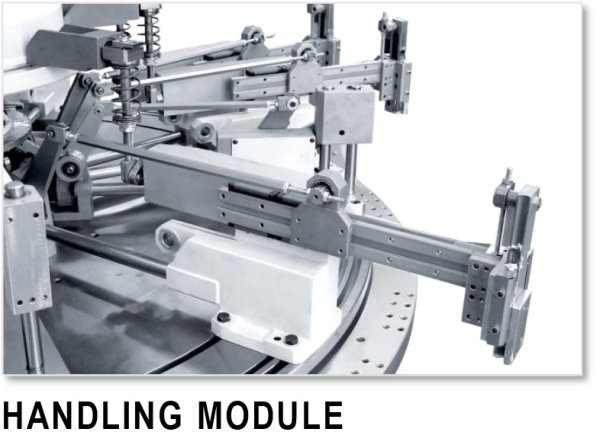

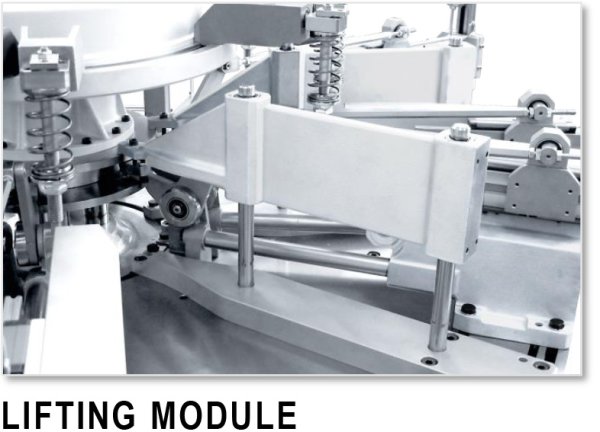

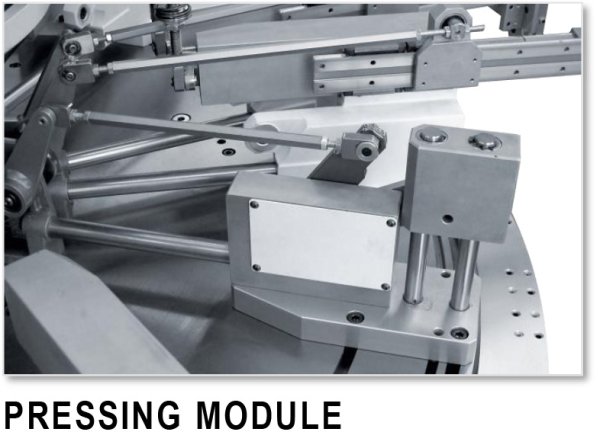

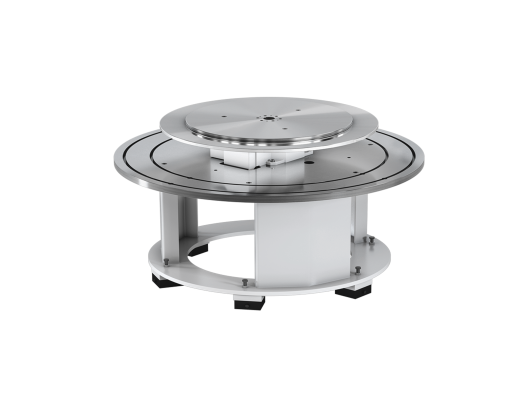

The PM assembly machine combines a rotary indexing table and handling modules to create a cost-effective system. By means of the central cam drive, up to 24 pick&place, pressing and lifting modules are cycled at the same time. The assembly machine is especially suited for high volumes, can be integrated easily and does not require any pneumatic handling modules.

Benefits

- Central cam drive for all module movements

- Standardized modular system

- Configured and assembled delivery

- Fast startup

- Easy control with only two drives

- Robust design

Technical Features

- Central drive with up to 24 pick&place, pressing or lifting modules

- High speed with up to 80 cycles per minute

- Repeat accuracy +/- 0.03 mm

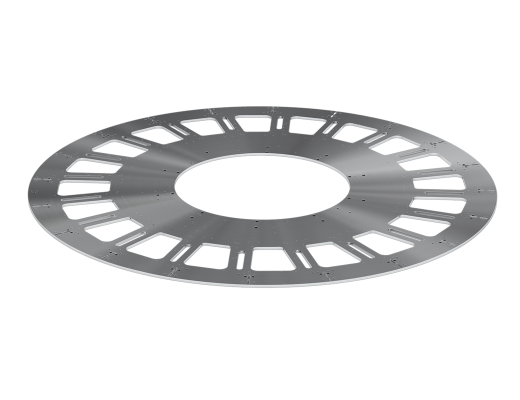

- High degree of flexibility via individual positioning of the handling units

- Easy T-groove positioning

- Adjustable pick&place modules and press or test modules