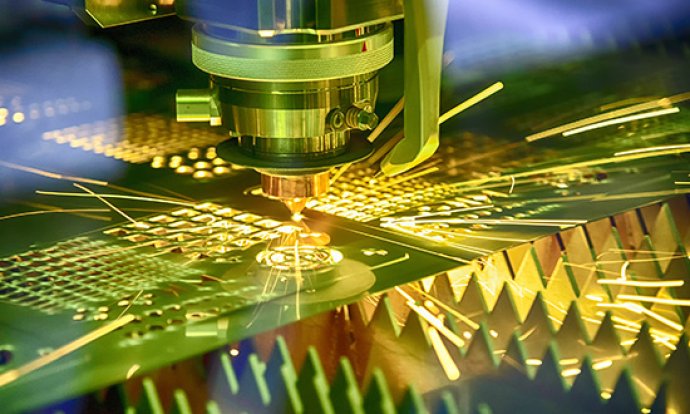

Laser Machining

From Car Body Parts to Sensors

Heavy loads and flying sparks or micrometer precision and cleanrooms. The demands of laser processing on the automation components in the various manufacturing processes could hardly be any more diverse. Thanks to our years of expertise in laser welding for the automotive sector, WEISS offers durable indexing and positioning solutions that can withstand the harsh ambient conditions. Not only that, customers from the micro-manufacturing sector also benefit from our high-precision indexer and multi-axis systems, which are perfectly designed for tasks in the electronics industry or medical technology industry.

Typical Processes

- Laser cutting and drilling glass

- Laser welding car bodies in the automotive industry

- Laser cladding, e.g. for engine technology components

- 3D laser printing for production of lightweight components

- Laser cutting printed circuit boards (depaneling), e.g. in the production of sensors

- Laser cutting in the machine tool sector, e.g. as a swivel head for the 4th and 5th axis with torque motors

- Laser marking small parts, e.g. in the middle of other process steps on our linear transfer system

- Laser welding, e.g. of sensors and housings in the medical field

- Laser drilling printed circuit boards

- Linear axes for setting the laser focus

- Manufacture of stents for the medical industry

- Welding battery cases

Application Examples

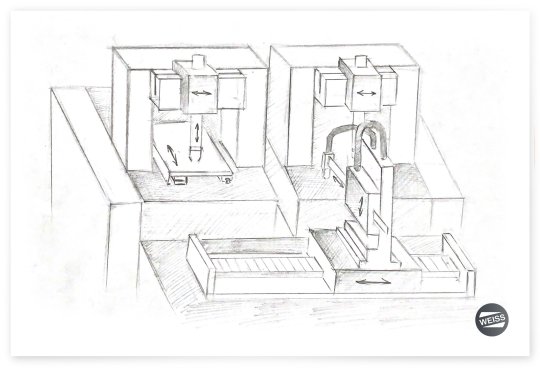

Depaneling of Printed Circuit Boards

Axis system with linear motor axes HN on granite for laser cutting of printed circuit boards

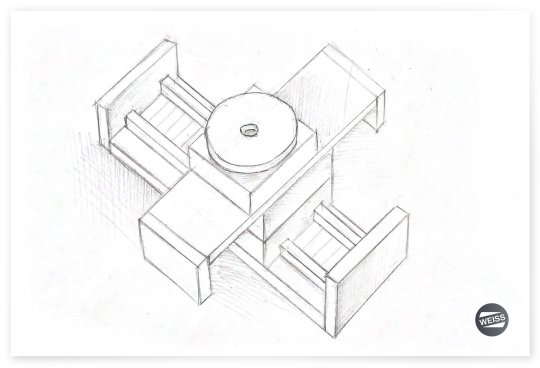

Laser Trimming and Laser Structuring of glass bodies

XY table combined with TO torque rotary table for perfect alignment