Disposables

Reach Maximum Productivity with Dynamics, Precision and Durability

When manufacturing and assembling medical or pharmaceutical disposables, the first key figure besides quality is the productivity. This is achieved through highly dynamic automation processes on the one hand, and high system availability on the other. WEISS offers a range of products that combine absolute reliability with maximum dynamics. Our linear-motor handling systems, torque-motor rotary indexing tables and delta robots come into play here, offering both durability and high positioning accuracy.

Typical Processes

- Manufacture of respirator masks

- Production of disposable syringes (joining and bonding processes)

- Production/assembly of catheters

- Production of hygiene products

- Packaging all kinds of products

- Production and inspection of surgical needles and suture threads

- Manufacture of contact lenses in combination with injection molding

Application Examples

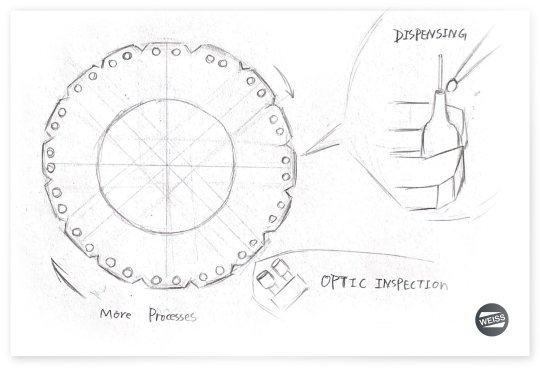

Syringe Assembly

Production of medical syringes with TO750 torque rotary table

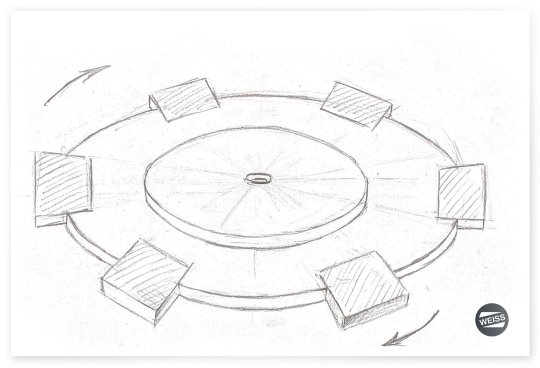

Mask Production

Assembly of FFP2 masks with freely programmable ring indexing table NR1500Z

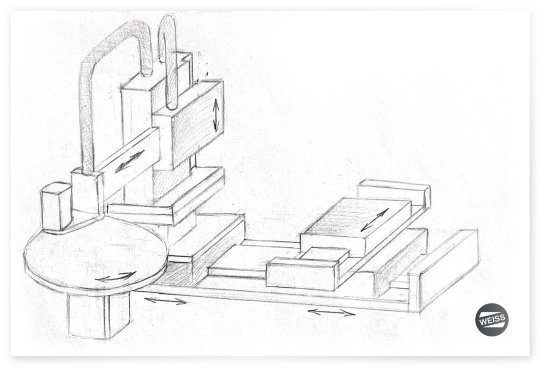

Optical Inspection of Needles

Multi-axis system for optical inspection of surgical needles