Automotive Components

Transporting, Moving and Positioning at Top-level Quality

The demands on assembly processes in the automotive industry are tremendous. For one thing, the range of components in the car, such as switches, sensors, control elements, electronic components and engine components, continues to grow. For another, assembly processes are becoming more and more complex. For over 50 years, WEISS has been providing international system integrators and automobile manufacturers with indexers and transfer systems for station linking as well as linear motor axes, Pick & Place modules and delta robots for handling tasks. The requirements for transporting, moving and positioning are always the same: maximum speed, the highest precision, long service life, absolute reliability and the smallest possible size are key features of WEISS products.

Typical Processes

- Motor assembly

- Laser cutting of sensors (depaneling)

- Automated screwing-in during component assembly

- Dispensing sealing material, e.g. when assembling control units

- Assembly of injection units

- Automated assembly of instruments

- Assembly of ball bearings

- Inspection systems for valves

- Assembly of connectors for cable harnesses

Application Examples

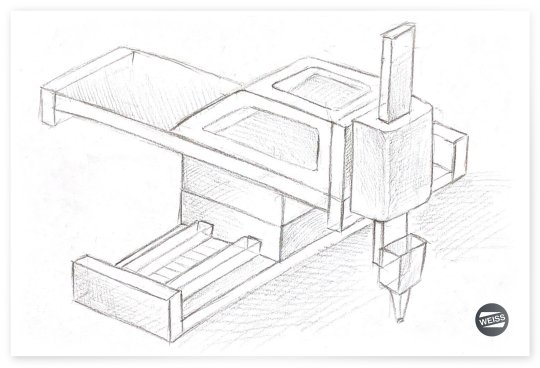

Dispensing with Gantry System

Dispensing of seals in plastic housings with high-precision Compact Gantry 3D portal

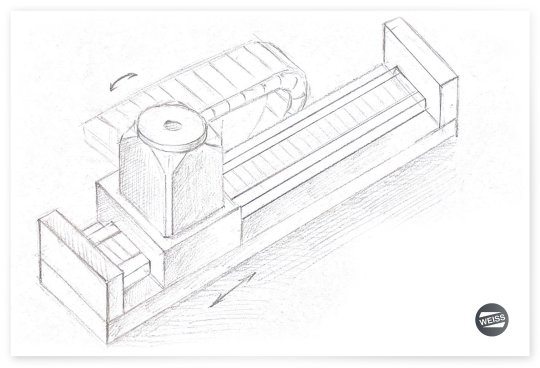

Spring Assembly

Insertion of springs in holes at high cycle rates with linear motor axis HN and rotary unit ST

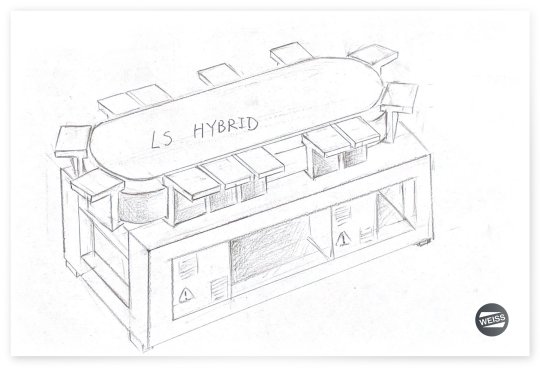

Assembly and Testing of Magnetic Valves

50 processes with short changeover times in one line with linear assembly system LS280