LS One linear transfer system: directly driven and ready for assembly

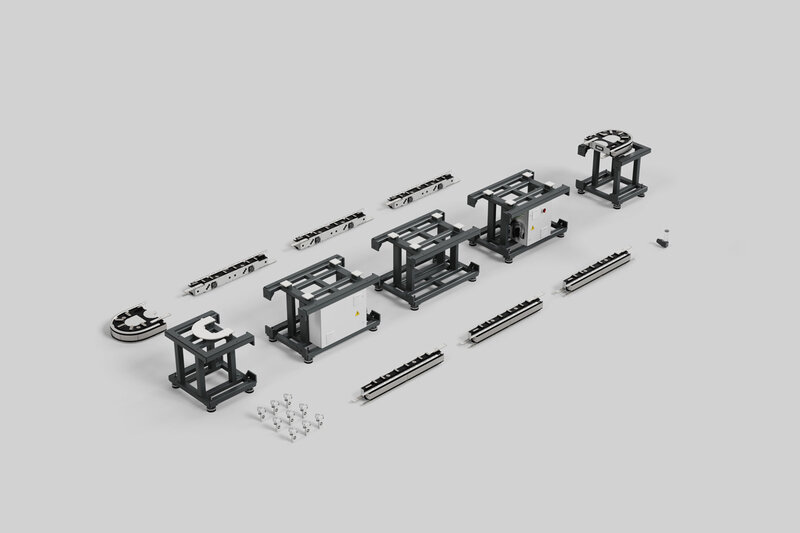

WEISS delivers its directly-driven linear transfer system LS One as a complete package. Pre-configured, pre-programmed and including the right frame and mounting plates, this saves the plant manufacturers and operators time during the setup and start-up.

LS One is the direct-drive transfer system in the WEISS linear transfer product family. The system is specially designed for tasks that demand the highest levels of precision and flexibility. Thanks to the linear motors, high dynamics and a freely selectable motion profile are possible. This makes LS One the most flexible linear transfer system in the WEISS portfolio.

Plug-and-Produce

The high flexibility is already evident during setup. The linear transfer system basically consists of just three modules: two motor segments 660 and 1320 mm in length and one redirection module. The daisy chain cabling provides the shortest installation time, reliability in operation and good accessibility for servicing. The pre-configured and pre-parameterized system can be freely programmed via the WEISS application software W.A.S. LS. Four movement scenarios have already been prepared in the control system.

LS One is delivered as a pre-wired, pre-commissioned complete system consisting of the transfer system (including the control cabinet) and the WEISS control system. The feasibility check, configuration, layout and simulation of the systems can be done for each customer in direct consultation with WEISS Application Engineering. The preparation and pre-parameterization of the LS One complete system saves system operators up to 30 percent time during start-up and enables a quick start of production.

Accuracy

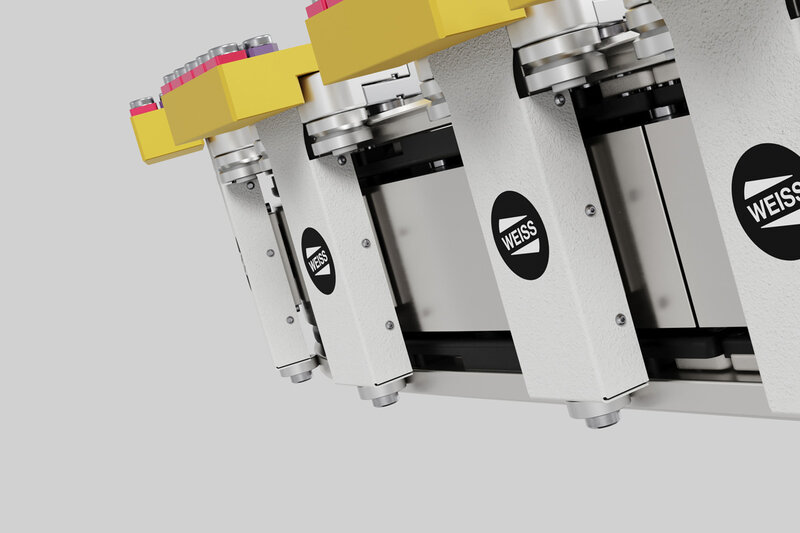

With the LS One, the constantly pre-tensioned steel rollers of the workpiece carrier are guided on V-rails. This “steel-on-steel” solution is robust and coordinated, making it low-wear and therefore highly precise over the entire service life. To enhance this precision, the workpiece carriers are also supported on a flat guide based on rolling elements. This allows for greater torques on the basis of workpiece weights and machining forces. Thanks to this design, the LS One's positioning accuracy reaches up to ± 0.03 mm in the X and Y direction. The workpiece carriers are designed for maximum load of 5 kg and can handle process forces of up to 300 N without support.

Tailor-made solution

LS One is just one of the linear transfer systems in the WEISS portfolio. A total of four different systems with nine drive types span a wide range of applications. The advantage is obvious for system integrators and plant manufacturers: WEISS is a partner that can help you create a wide range of assembly lines. Moreover, the linear transfer systems are equipped with the W.A.S. LS on the control system side, which can be used without in-depth programming knowledge and easily integrated into the higher-level system control. At the same time, the transfer solutions can easily be combined with additional automation components in the WEISS portfolio. The in-house WEISS Application Engineering team develops the right solution in cooperation with system integrators and system operators.