Increased Productivity Thanks to Direct Drive

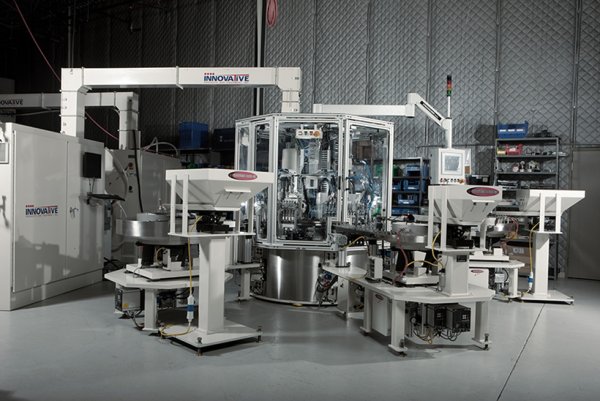

In order to increase the performance to 75 cycles per minute, the American custom machine builder Innovative relies on rotary tables and handling units with direct drive.

At a Glance

- A change from a linear system to a rotary indexing table was necessary to achieve the desired increase in speed of the system for assembling and testing plastic components used in irrigation plants

- The combination of TO 750 torque rotary table and HP Pick&Place units with direct drive was the system of choice

- It was possible to increase the performance of the complete system by 25 percent to 75 cycles per minute

Challenge

With a speed of 60 cycles per minute, the existing system for assembling and testing plastic components used in irrigation plants had reached its technical limits. In order to achieve the desired gain in speed, the US-based custom machine builder Innovative had to switch from a linear system to the rotary indexing table.

Solution

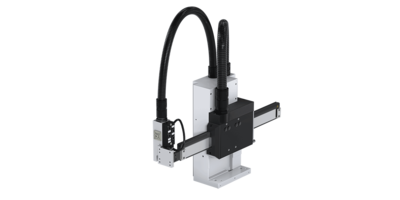

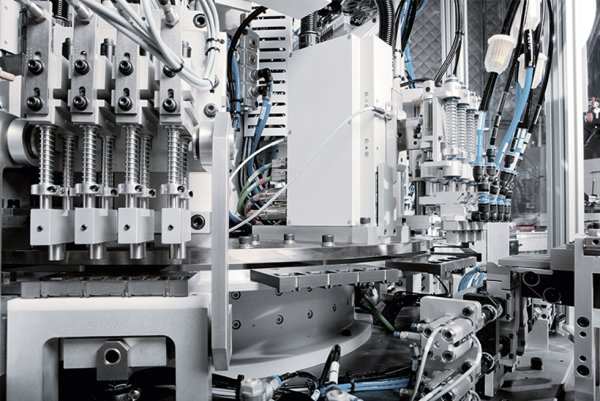

Thanks to its highly dynamic performance and repeat accuracy, the user-programmable TO 750 torque rotary indexing table was chosen as the system basis. Five HP 140 Pick&Place units take care of handling the plastic parts. The direct drive combination made up of table and handling units are a perfect match and increase the system's performance by 25 percent to 75 cycles per minute. And as far as the control system was concerned, adapting it to the preferred SPS from Siemens was no problem.