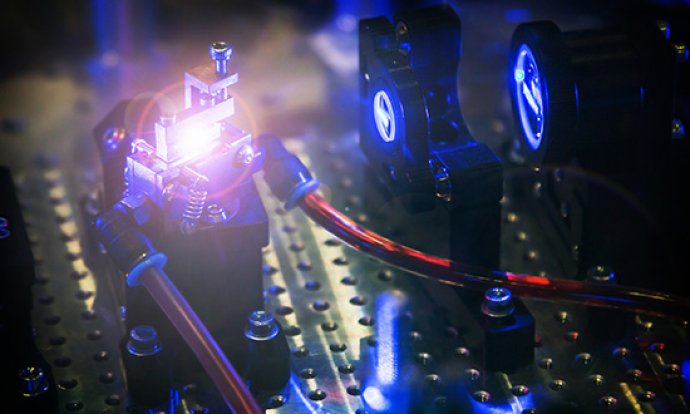

Photonics

From the Lab to the Industry

Fueled by Industry 4.0 applications, the rise in the volume of data required worldwide is placing increasing demands on the telecommunications infrastructure. More and more fiber-optic systems are coming into play. Due to the growing quantities, the requirements for automation during production are also increasing. The main issue here is to precisely align the glass fibers or entire arrays with each other. Today, standard applications require increments from 50-100 nm. Initial laboratory applications in the area of silicon photonics (SiPh) require increments of around 5 nm. WEISS is developing customized solutions for this market as well – solutions that meet market requirements and, at the same time, are fit for 24/7 use in the industry.

Typical Processes

- XY tables for positioning SiPh wafers

- Aligning glass fibers to each other with a 3-axis system

- High-precision alignment of fiber arrays with increments of around 50 nm

- Testing SiPh bonds

Application Examples

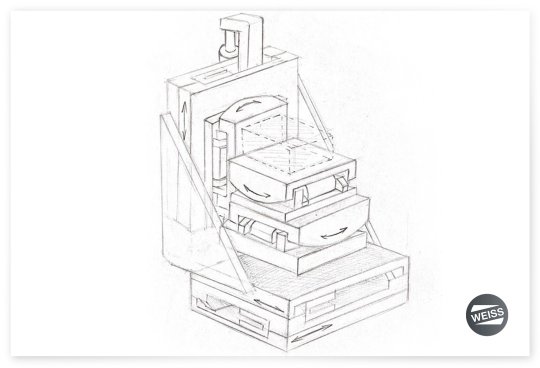

6DoF Alignment

Adjustment of fibers or fiber arrays

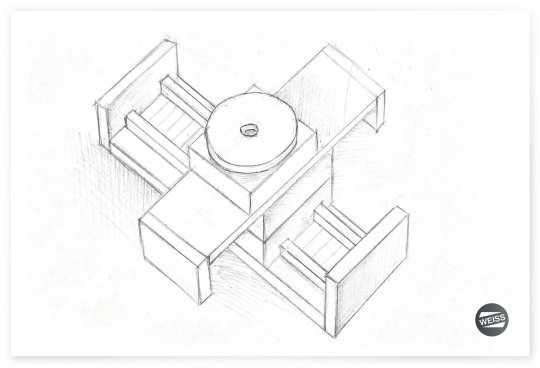

Wafer Probing

Test of optical circuits with customized XY system