Six Linear Motor Axes in One Servo Cell

Dynamics, speed and stability in the smallest space

At a Glance

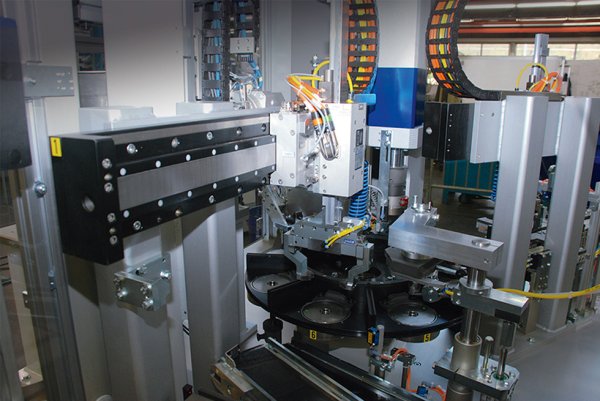

- Six WEISS linear motor axes integrated into the servo cell

- High demands on dynamics, precision and compactness

- Quick conversion to 24 different product variants

Challenge

The high-performance automatic units from OKU are used all over the world, including in the metal, plastics, electronics and automotive industries. The plant manufacturer needed a space-saving handling solution for a servo cell used for the assembly of special ball bearings. Due to the high demands regarding dynamics and precision, spindle drives and toothed belts proved inappropriate.

Solution

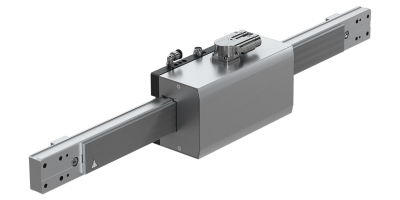

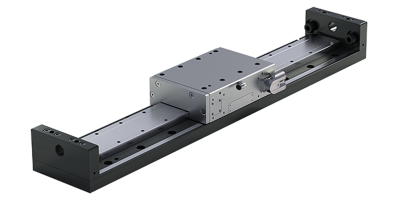

For the first time OKU employed user-programmable linear motor axes in combination with a TC rotary indexing table for the assembly of ball bearings. Extremely high dynamics and precision, a compact design and the ability to connect to third-party drives were the deciding factors. A total of six axes, a combination of HN 100 and HL 100, work together in a small space – featuring a maximum acceleration of 40 m/s2 and a maximum speed of 4 m/s.