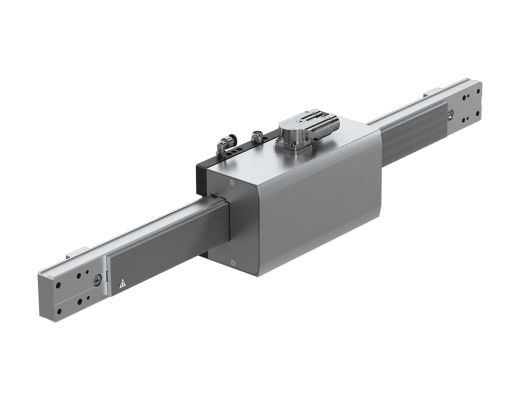

LS One direct drive linear transfer system

Dynamic, flexible and efficient, thanks to the linear motor drive

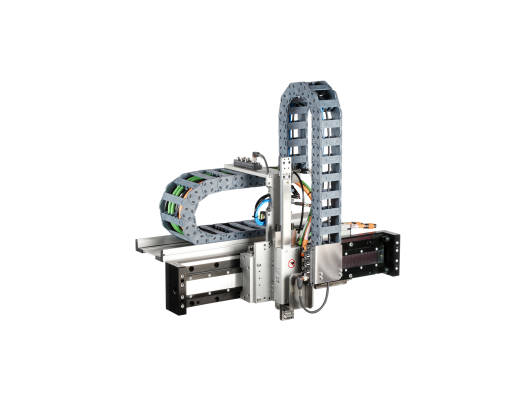

With LS One, users rely on a subsystem based on the plug & work motto. It is flexibly configured, pre-configured and easy to start up. Thanks to the linear motor module, the movements of each workpiece carrier can be programmed independently and freely. For certain types of processing, the linear motor module replaces an additional process axis.

Benefits

- Individually configurable transfer solution

- Can be retrofitted at any time

- Freely programmable workpiece carriers in all parameters

- Efficient assembly of small batch sizes or batch sizes with high variance

- Exceptional reliability, even for delicate components and complex processes

- Fast start-up and therefore start of production

Technical Features

- Modular system for high level of flexibility

- Direct drive with minimum installation effort

- Easy system reconfiguration via software

- High precision thanks to direct drive and guiding system

- Prepared, pre-commissioned system

Technical Data

-

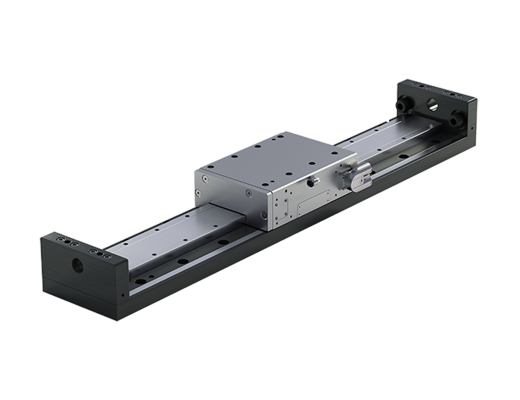

Linear motor module 1320 WxHxD :1320 x 170 x 632 mm

-

Linear motor module 660 WxHxD :660 x 170 x 632 mm

-

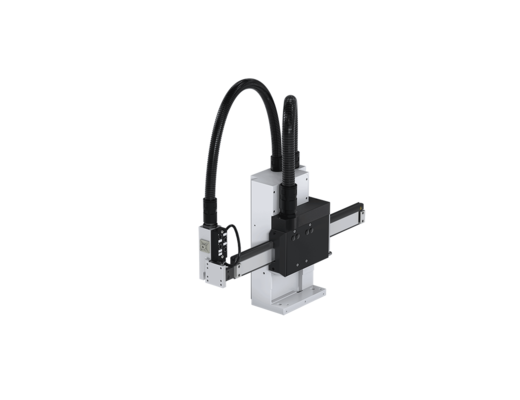

Redirection module WxHxD :638,5 x 170 x 632 mm

-

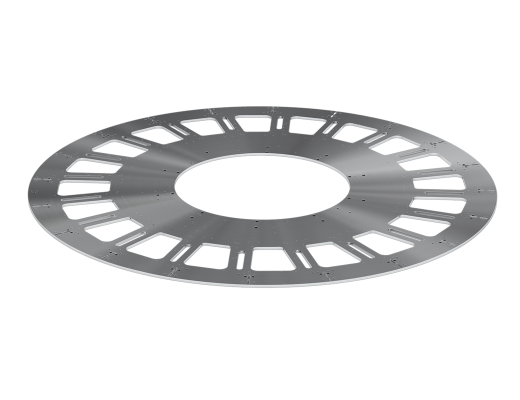

Workpiece carrier (WC) plate length :Min. 114 mm (multiple nests possible)

-

Max. loading :Up to 5 kg

-

Installation pos. :Horizontal

-

Structure :Oval mit 180°-Ecke

-

Direction of movement :Counterclockwise (CCW), clockwise (CW)

-

Linear motor module positioning accuracy :± 0,03 mm (x-, y- & z-Richtung)

-

Redirection module positioning accuracy :± 0.03 mm (x, y and z directions)

-

Power supply :200-480V, 50-60Hz

-

Software :W.A.S. (WEISS Application Software)