Be productive, & transform yourselves!

WEISS enables customers to flexibly configure production with LS Hybrid. In this dialog, CTO Ralf Steinmann swaps observations with CEO Uwe Weiss about innovative linear transfer systems for meeting customers’ need for “timed positioning”.

For years, companies have been clamoring for automated, flexible manufacturing processes that ensure increasing volumes, smaller batches and faster production. Nowadays, it’s essential to efficiently link the individual steps executed in production systems to ensure that feeding, ejection, buffering, separation, and positioning of workpieces or workpiece carriers will work. As a “complete supplier for assembly automation,” WEISS is accomplishing this with the new LS Hybrid linear transfer system.

Uwe Weiss “It’s really remarkable that so many customers have such similar expectations of production lines. They want the ability to manage diversity to handle a wide range of products and formats. Plus efficient control for greater output, and finally more flexible systems with new, extended functionality.”

Ralf Steinmann “Adaptable production processes are an absolute must these days. It must be quick and easy to integrate both transfer and handling systems in production lines and activate them as required. This is an essential prerequisite for competitive manufacturing. We’ve therefore also taken the approach of extending a conventional rotary indexing solution developed by us and implementing a linear stretch with transfer and positioning functions.”

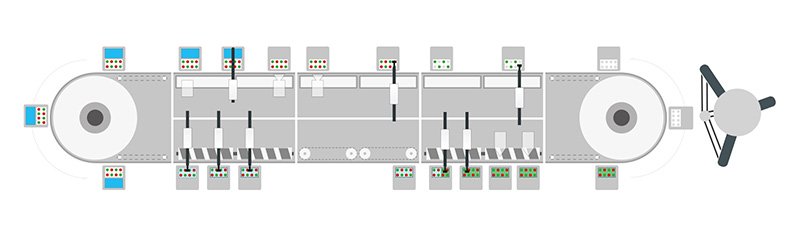

Regardless of whether it is a cam drive, direct drive, corner or conveyor section - the LS Hybrid transfer system can be assigned individual movement profiles in the system, which gives production completely new perspectives. Precise and independently moving shuttles can be moved with intelligent system software in such a way that an increase in productivity with up to 40 % shorter transport times is possible: whether by combining product flows, parallelizing processing stations, or increasing error tolerances. Overall, more processes can be arranged in less space.

Uwe Weiss “The LS Hybrid linear transfer system optimizes a conventional pallet transfer system by adding highly dynamic features that give the customer more latitude for creativity. Using more functions at once also means changing the underlying principles of production, doesn’t it?”

Ralf Steinmann “It’s important to consider the increased productivity and processing ability in contrast to rotary indexing tables and clocked cycles. Whereas a table has a fixed cycle, the LS Hybrid permits both double and single machining in a single system, and synchronous and asynchronous or even reversible movements are also possible. In a synchronized chain, by comparison, the system’s maximum size is limited and so is its loadability in relation to its length. It’s also impossible to uncouple process stations.”

Uwe Weiss “It sounds like a generational change, with this flexible transfer system maximizing throughput while minimizing the required space. Does this mean that you can increase output with flexibly controllable shuttles and produce very large volumes with single-digit cycle times?”

"Compared with a classic pallet transfer system or cycle chains, the LS Hybrid has unique characteristics that make this system ideally suited for flexible and economical production that is quick and easy to place into operation." Ralf Steinmann, CTO, WEISS Group

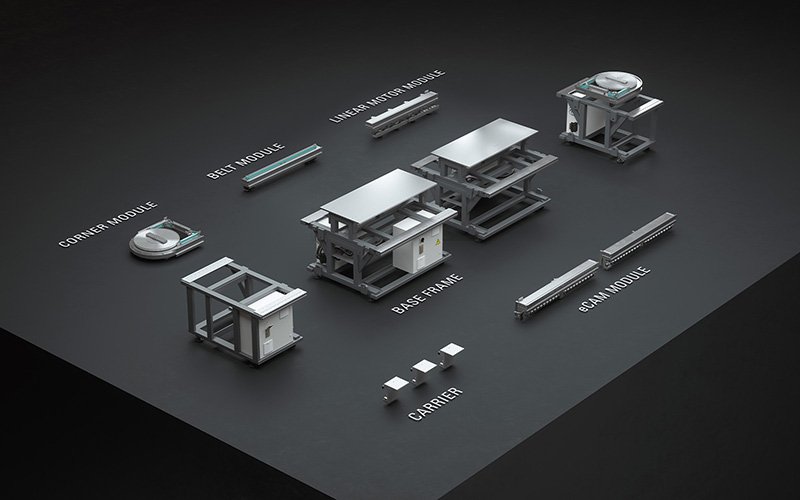

Ralf Steinmann “Fifty cycles per minute are easily achievable, which should be attractive not only to mass producers but also large series producers. The key is the modular linear transfer system, which allows flexible system configuration. The novel ‘eCAM module’ combines the advantages of a conventional high-precision cylindrical cam drive with juxtaposition of the traversing profile of controlled servo drives. The trajectories of the workpiece carriers can therefore be very easily adapted to the application.”

Uwe Weiss “This means that it’s now possible to automate difficult and complex processes that used to have to be executed manually. In combination with other handling and pick-and-place process and assembly and testing stations, this gives rise to an adaptive production system based on the LS Hybrid. As another plus point, the user benefits from a completely wired and tested plug-and-play approach for very easily integrating the linear transfer system in the production line. This makes it possible to plan more reliably, since rapid on-site commissioning is ensured.”

Ralf Steinmann “This system is a major improvement on the older, strictly linear product flow. It’s a platform for high-performance assembly. Typically, the slowest station sets the pace for the overall system. For example, the workpiece carriers can work very dynamically, accelerating right after executing a defined operation and then falling back into step with the product stream. This is especially interesting to those who want to achieve greater efficiency.”

This six-part assembly is a prime example: It decreases your overall footprint while utilizing each independently controlled carrier. Programming infinite positions and varying speed and acceleration/deceleration values assists in optimization of the process and lowers the overall cost of integration. Important process forces are supported by a guide system and lateral locking of the tooling carriers. The flexibility offered when using the WEISS handling units and process modules allows for smooth communication between components, which will provide,

at times, more than double the throughput.

Uwe Weiss “I also look at it from the perspective of ensuring a continuous flow of production, since all of the upstream and downstream machines work uniformly. This reduces wear, energy consumption, and noise. I also see an important contribution toward achieving sustainability goals, like a reduced carbon footprint, reconfigurability and reusability, and extending the range of applications, which are no longer limited to a single product. In the final analysis, building smaller also means reduced costs for cleaning, climate control, and protecting investments in machinery.”

Ralf Steinmann “The system’s overall efficiency is improved by this intelligent transfer system. I’m absolutely convinced that its assembly and handling technology ranks among the innovations that are making automated production faster and more efficient than is possible with conventional methods.”

Uwe Weiss “We can also tap the potential of simulations, which make it possible to design faster machines and processes. Or genuine concurrent engineering with software programming and virtual commissioning that take place simultaneously with mechanical configuration. Systems like this are essential for achieving smooth production processes without major downtimes, although it’s essential to mention one thing: decisions aren’t driven by innovations alone. A large role is also played by engineers’ creativity and insights for changing things and introducing improvements.“

"Versatile, flexible, efficient: With its modular design principle, the LS Hybrid transfer system sets standards in the adaptation of application requirements. Depending on the process step, the suitable module with the appropriate drive technology can be used for economical production." Uwe Weiss, CEO, WEISS Group

Ralf Steinmann (laughs) “Yes, it’s really amazing that such a cam-controlled linear-motor conveyor drive can be the innovative leap forward in drive technology that gives entire production systems a new and, yes, even more beautiful face. The approach of designing the business end to be highly flexible and dynamic with linear drives, with really simple cam-controlled return transport, is simple, smart, and cost-effective. In my mind, these are the main reasons to technologically revamp production.”

Uwe Weiss “Let’s talk soon about the applications and how to reap the benefits in the application. I’m excited to see exactly which assembly processes can be redesigned for greater efficiency with this system …”

Ralf Steinmann “It isn’t the individual assembly processes but the overall picture that matters. In my opinion, rounding out an assembly line with the LS Hybrid results in features that give you greater flexibility and more creative latitude for applications. The transport times are also shortened, which promises greater cost-effectiveness.”

Uwe Weiss “And that – and I know I’m repeating myself here – puts on the focus on this system’s explicitly changed assembly processes, doesn’t it?”

Ralf Steinmann “I’ll get back to you with the right applications, it’s a promise!”

DISCOVER MORE

ls-hybrid.weiss-world.com