Out with Pneumatics, in with the Direct Drive

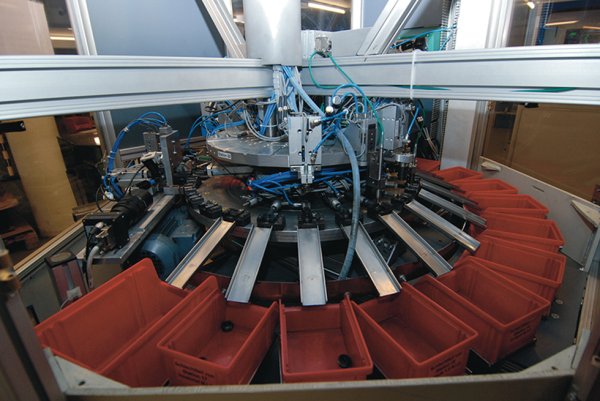

Cycle time cut from one second to 0.3 seconds: torque rotary table replaces pneumatic solution in test bench for precision turned parts

At a Glance

- Changeover from a pneumatic system to a direct-drive rota-ry table solution

- Significant reduction in switching times to 0.3 seconds

- The fact that there is no maintenance and compressed air preparation required brings additional savings

Challenge

Significantly reducing the cycle time – that was the key requirement demanded by the custom machine builder Gießler from their test bench performing the final quality check of tension screws used in common rail injection systems. The pneumatic rotary indexing table used previously had reached its limits.

Solution

Faster, more cost-effective and virtually maintenance-free. The arguments for switching from the pneumatic solution to the direct-drive TO 220 rotary indexing table were simply compelling. For instance, it was possible to reduce the switching time from one second to 0.3 seconds – saving time and therefore costs. In addition, the direct-drive rotary table is maintenance-free and there is also no need to regularly replace the shock absorbers of the pneumatic rotary indexing table.