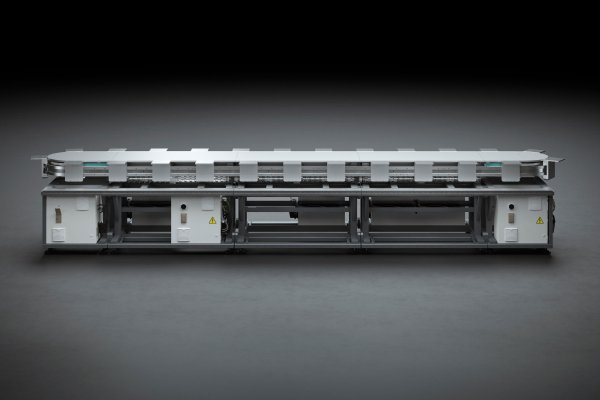

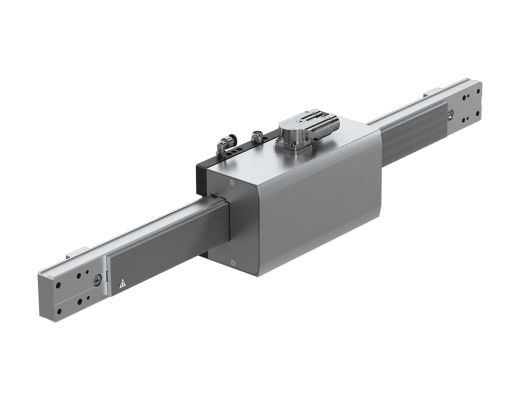

LS Hybrid Linear Transfer System

For more output and flexibility

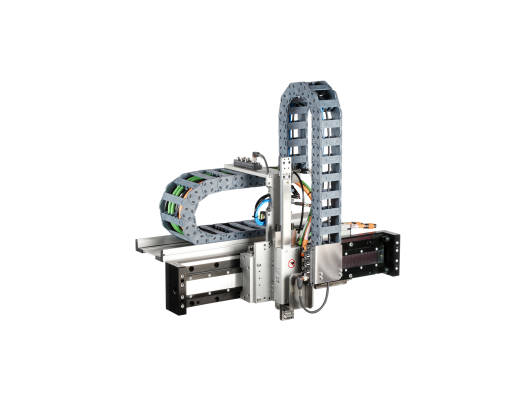

The LS Hybrid transfer system optimizes a classic pallet transfer system with mechatronic and highly dynamic properties. These features add more flexibility and efficiency to production lines. WEISS will design the drive technology and plug & produce properties with variable design freedom in accordance with the customer application. In addition, the system allows a longitudinally timed flow assembly to have more process capability, which is ensured by fast, precise carrier transport.

Machine concepts that are superior to purely linear machines with a rigid product flow are now possible. This makes the LS Hybrid a poster child for modern assembly automation that works efficiently as an integrable transport platform and reaches new productive spheres.

Benefits

- Performance increase: 20% higher number of cycles

- Dynamics: 40% shorter transport times

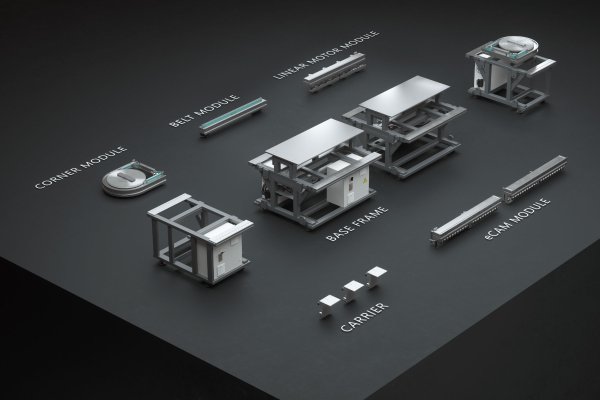

- Modular principle: drive modules for any requirement

- Efficiency: more processes in less space

- Process reliability: fast workpiece transport with high process capability of the transfer system

- Pure customer orientation: demand-oriented investment

- Plug & Produce: fast commissioning of the system

Technical Features

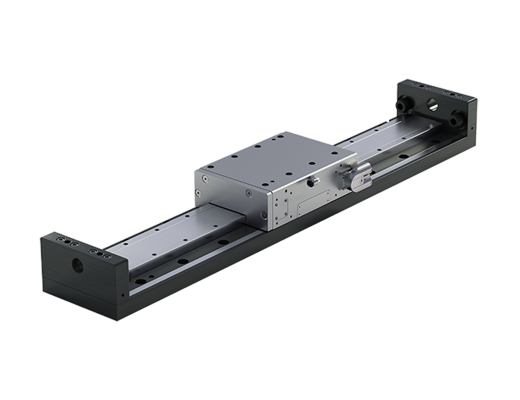

- Self-designed innovation with eCam Module

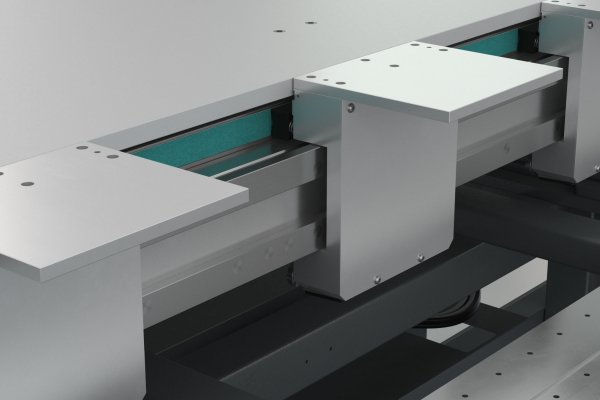

- Superimposed motion profiles of cylinder curve and servo motor

- Flexible system configuration based on a modular design principle

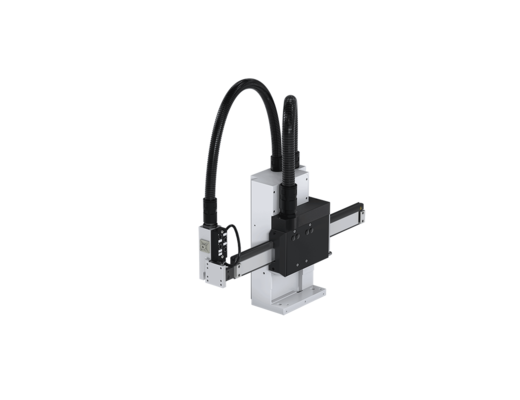

- A combination of different drive types: eCam and belt module or linear and belt module, each with a redirection module

- WEISS Application Software (W.A.S.) makes commissioning quick and easy

- Approx. 60 parts per minute, depending on stroke and process time

- Jerk-optimized motion profile

- Absolute locking without additional indexing

- Wide range of parts due to loading up to 10 kg

- Position, acceleration, speed and direction of movement freely programmable with linear motor module high precision (± 3/100 mm in X, Y and Z)

- Almost seamless stringing together of any number of eCam Modules with the same stroke possible

Technical Data

-

cycles per minute :ca. 60

-

max. load :bis zu 50 kg je Kettenglied (vertikale Einbaulage)

-

workpiece exchange time :0,25 - 0,40 s

-

process forces (without support) :ca. 1000 N

-

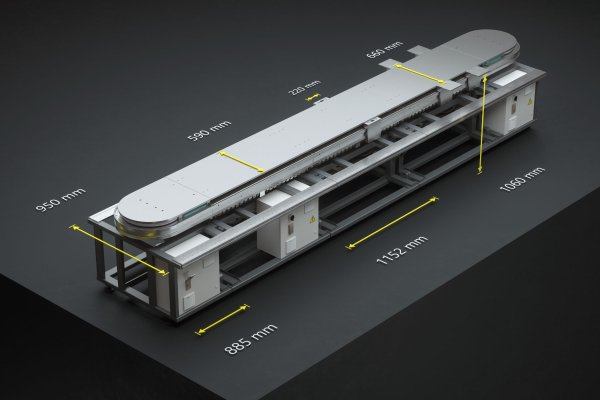

length of workpiece carrier :220 mm

-

length of tooling carrier plate :200-500 mm

-

stroke e-cam module :64, 128, 256, 512 mm

-

repeatability e-cam module (X-axis) :± 0,03 mm

-

repeatability linear motor module (X-axis) :± 0,02 mm

-

repeatability (Y-, Z-axis) :± 0,03 mm

-

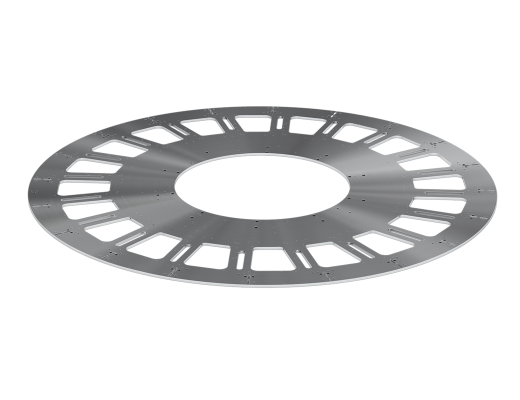

positioning accuracy corner module :± 0,15 mm

-

Fieldbus interface :EtherCAT, Profinet, EtherNet/IP

-

W.A.S. (WEISS Applications Software) incl. :yes

-

cell length :1152 mm

-

Power supply :200-480V, 50-60Hz

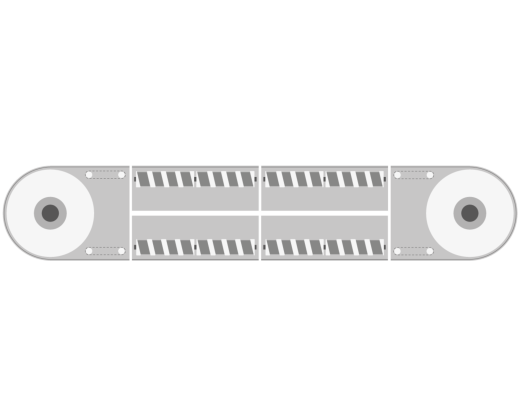

Configuration Example

LS Hybrid with 2 eCam Modules on each side. For application requirements with consistent indexing at highest precision and dynamics.

-

eCam Module (stroke options):64, 128, 256, 512

-

eCam Module (# process stations):2x34, 2x16, 2x9, 2x4

-

Linear Motor Module (line length):-

-

Belt Module:-

-

Corner Module (# process stations):Optional +2

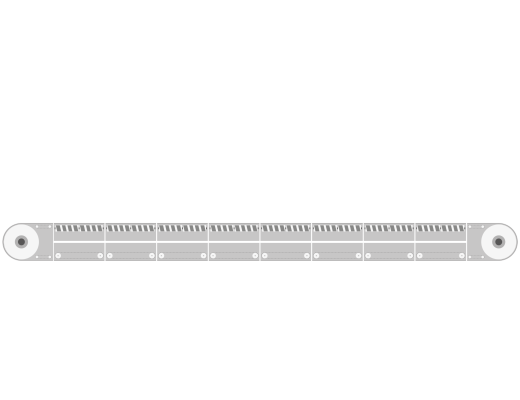

Configuration Example

LS Hybrid with 8 eCam Modules on one side for application requirements with consistent indexing at highest precision and dynamics. 8 Belt Modules on the opposite side provide the fast return.

-

eCam Module (stroke options):64, 128, 256, 512

-

eCam Module (# process stations):142, 70, 36, 19

-

Linear Motor Module (line length):-

-

Belt Module:Yes

-

Corner Module (# process stations):Optional +2

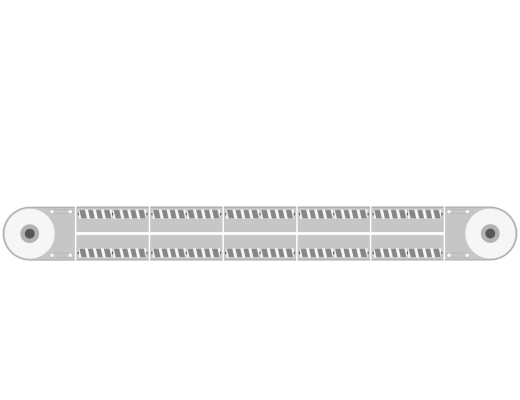

Configuration Example

LS Hybrid with 2 eCam Modules on each side, each decoupled by 1 Double Belt Module for transport between process stations. Combination of different firmly interlocked process positions using different strokes with highest precision in each position.

-

eCam Module (stroke options):64, 128, 256, 512

-

eCam Module (# process stations):4x16, 4x7, 4x4, 4x2

-

Linear Motor Module (line length):-

-

Belt Module:Yes

-

Corner Module (# process stations):Optional +2

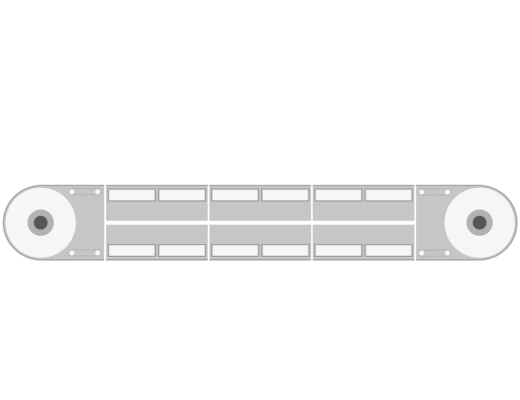

Configuration Example

LS Hybrid with 3 Linear Motor Modules on each side, for freely definable positioning and process patterns as well as motion sequences with high accuracy requirements and cycle rates.

-

eCam Module (stroke options):-

-

eCam Module (# process stations):-

-

Linear Motor Module (line length):2x3254mm

-

Belt Module:-

-

Corner Module (# process stations):Optional +2

Configuration Example

LS Hybrid with 5 eCam Modules on each side, virtually endlessly couplable and expandable without intermediate belts. For application requirements with consistent indexing at highest precision.

-

eCam Module (stroke options):64, 128, 256, 512

-

eCam Module (# process stations):2x88, 2x43, 2x22, 2x11

-

Linear Motor Module (line length):-

-

Belt Module:-

-

Corner Module (# process stations):Optional +2