Metrology

Precision for All Test Tasks

The demands for high quality in produced components are getting higher every day. This makes quality assurance in automated production ever more important, especially in the automotive, mechanical engineering, electronics and medical technology sectors. Industrial measurement technology can increase the production output by accelerating test processes, avoiding iteration loops and shortening cycle times. Coordinate measuring systems, optical systems and multi-sensor systems rely on components that rotate, move and position with high precision and dynamics, such as the indexers and axis systems from WEISS.

Typical Processes

- Optical inspection of filled ampoules in medical technology

- Optical inspection of printed circuit boards

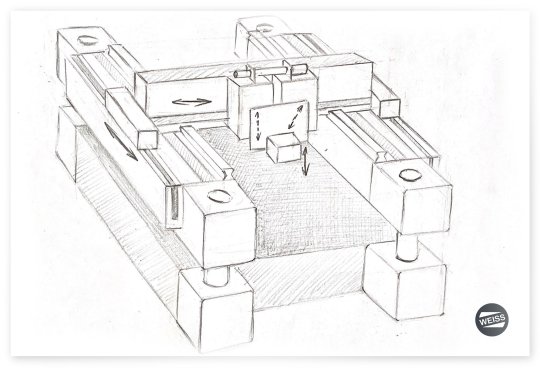

- Surface inspection and measurement with our high-precision MK cross tables

- Inspection systems of printed circuit boards, typically designed with customized XY solutions

- Systems for material and structural analysis, e.g. for engine components

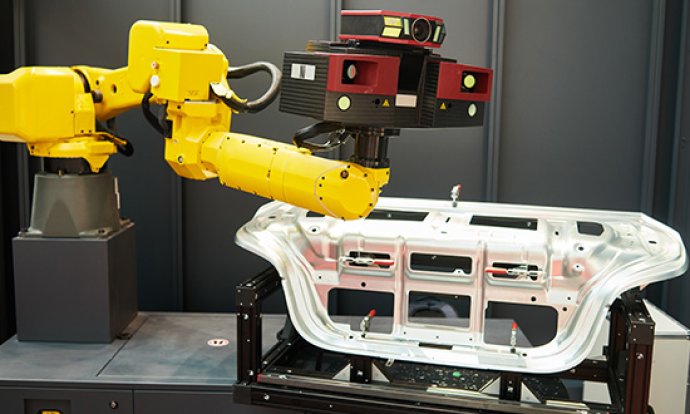

- Indexers for non-contact measurement of car body parts and other large components with free-form surfaces

Application Examples

Visual Inspection

Visual inspection of vehicle parts in 3D with heavy duty table CR700 or freely programmable rotary indexing table NC320

PCB Inspection

Granite system for optical inspection