Individual assembly processes on one platform

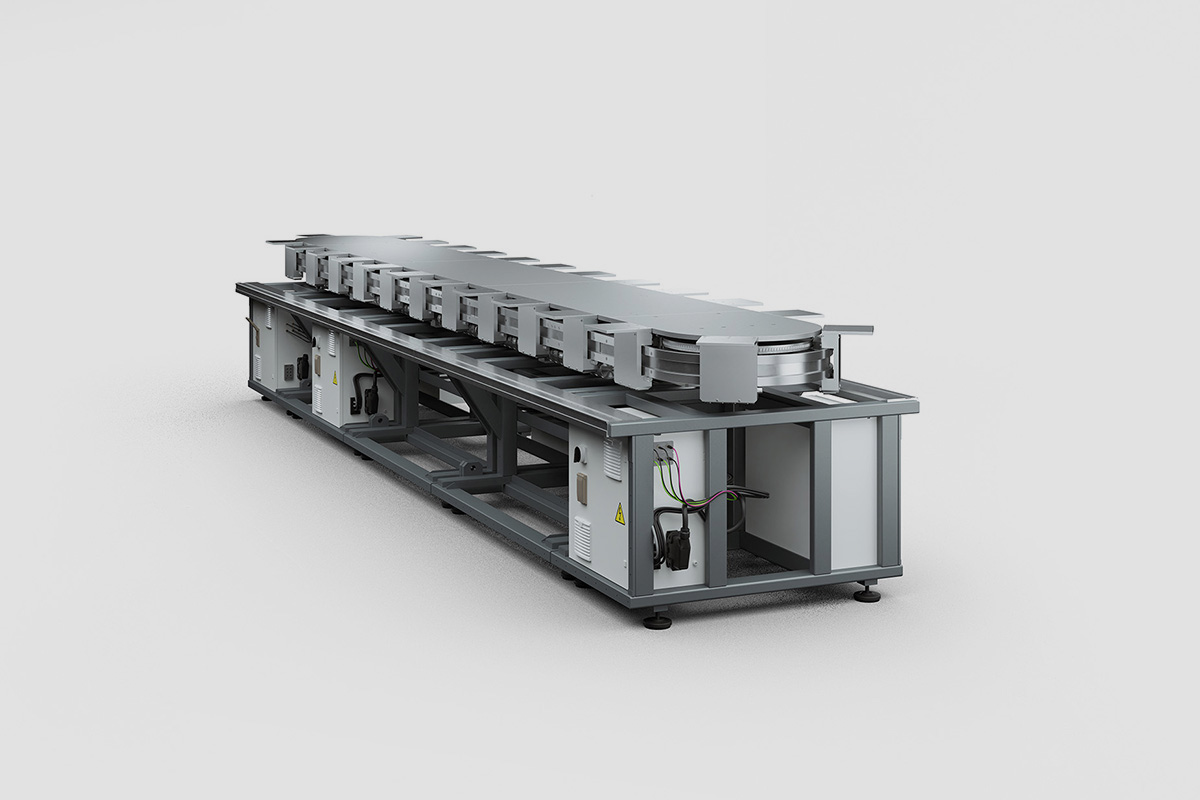

WEISS has launched LS Hybrid, a linear transfer system that can flexibly map individual positioning tasks on one platform. Be it joining, welding, screwing, pressing or printing – the LS Hybrid particularly demonstrates its advantages in small parts assembly.

When process steps with different requirements for speed and cycle time come in series, the linear transfer system from WEISS is the right automation solution. On LS Hybrid, users can map a wide range of assembly tasks on one fully automated platform.

From battery packs and small gears to toothbrushes

LS Hybrid is designed for fully automated parts transport. Material can be fed automati-cally or manually. The system can handle workpiece carrier sizes of up to 500 millimeters and loads of up to 10 kilograms. The range of parts is accordingly wide. With LS Hybrid, it is possible to map assembly lines for small gears, control units, electromechanical assemblies, cable harnesses, various plastic components such as housings or parts for the consumer goods industry.

Further, as a result of mechanical locking, workpiece carriers accommodate very high process forces of up to 1000 N without support. This is relevant for press-in processes in connector assembly, pad printing, inserting sealing elements or setting screw connections, for example. At up to 60 cycles per minute and transport times that are up to 40 percent shorter, LS Hybrid can ensure a very high number of process steps in a small space. This makes cycle times shorter and saves space in assembly halls. Workpiece carrier transport and positioning at processing stations are highly dynamic process steps, yet LS Hybrid carries them out without jerky approaches or braking. The workpieces stay in position. The linear transfer system features a level of precision of ± 0.03 millimeters in the X, Y and Z directions.

Modularity and drive concept

The longest LS Hybrid sold to date was around 11 meters long. The transport cams installed in it alone were around 9 meters. It is driven by two motors harmonized in perfect synchronicity. Thanks to the modular structure, very long linear transfer systems with a range of different processing stations can actually be implemented on one platform. The longest LS 280 with a 100% mechanical cam drive was over 30 meters long.

The workpiece carriers on LS Hybrid are reliably driven by eCam technology developed in-house by WEISS. In eCam technology, the automation specialists combined the advantages of the cam drive with the movement profile of a servo motor. Overlapping the cam shortens the overall cycle times.

W.A.S. Control Package

The W.A.S. (WEISS application software) control package simplifies the configuration and commissioning of the basic system and its adaptation to customer requirements. At the same time, it is easily and quickly connected to the higher-level system control. Movement profiles that users can call up to implement a range of sequences quickly and easily are stored in the W.A.S. This way, even smaller batch sizes with significantly shorter product throughput times can be implemented.

Integral platform

In the WEISS World – as the automation specialists from Buchen, Germany, call their mechatronic platform – mechanics, electronics and controls are perfectly harmonized. As a result of this modular concept, LS Hybrid can be combined with other components from the WEISS portfolio. The interplay with HP pick & place units or DR delta robots yields a subsystem that can be integrated into the overall system as an operational unit.