Condition Monitoring

Digitizing the maintenance processes is often a task still to be accomplished. Monitoring the machines with Condition Monitoring is the first stage of data enhancement so that risks in operation can be reduced by intelligently detecting production deviations.

Digitizing the maintenance processes is often a task still to be accomplished. Monitoring the machines with Condition Monitoring is the first stage of data enhancement so that risks in operation can be reduced by intelligently detecting production deviations.

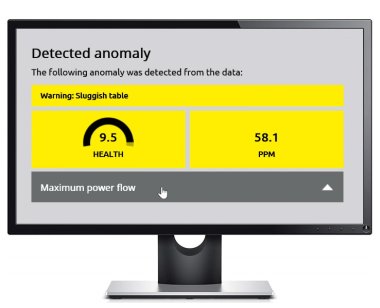

Condition monitoring allows physical parameters to be continuously recorded, evaluated and monitored. Smart sensors can be used for vibration and torque monitoring, measuring temperatures and power consumption and displaying machine states.

For example, on the TC150 rotary indexing table with the EF3 rotary table control or HP70 with the W.A.S.2 control package, operational changes and irregularities can be quickly and easily detected, which signal a warning when limit values are exceeded. Equipping the system with the added value of data technology, ensuring data transfer via the web server or the field bus interface, is a system-oriented IoT solution at device level that WEISS will soon be offering its customers - a pointer to added value with digitization based on mechatronics. An increasing number of WEISS products are equipped with OPC-UA interfaces, allowing the valuable monitoring signals and messages to be transmitted directly to target applications such as SCADA, MES, PDA, CMMS or ERP without the traditional data paths of the automation pyramid having to participate in the data exchange.