A R/EVOLUTIONARY LEAP FORWARD

IN ASSEMBLY TECHNOLOGY.

ADVANCE TO THE NEXT LEVEL

NOW WITH LS HYBRID!

Today’s linear transfer systems need to deliver three things: greater output, smaller batches, and more product versions. And they need to accomplish this in less space in tandem with new production technologies. This calls for assembly systems with greater performance, efficiency and dynamics – in addition to greater flexibility and minimal retooling times. Plus a compact design and scalability. LS HYBRID makes all of this possible. It may be only a small step up for the WEISS linear transfer system, but it’s driving a major revolution in assembly processes.

„We’re familiar with the requirements. And our LS HYBRID is the world’s only flexibly combinable hybrid drive system for meeting the needs of smart inline assembly while giving users a high level of versatility.“

Fabian HÜBNER, Head of Product Management, WEISS Group

GET UP TO VOLUME FAST –

WITHOUT ANY IFS, ANDS OR BUTS!

Time is money, and modern linear transfer systems that run fast and are quickly reconfigurable are ideal for minimizing the costs of assembly line production. Reliable functionality and ease of handling are essential for maximizing productivity.

EVERYTHING THAT BOOSTS THE EFFICIENCY OF PRODUCTION:

- Increase the performance of your production line

by reducing cycle times and maximizing throughput - Achieve greater efficiency by accommodating more processes in less space

- Slash retooling and reconfiguration times with Plug-and-Produce

- Get the system running sooner and complete projects faster

Outstanding Characteristics.

The facts at a Glance.

60

cycles

per minute

=

performance increase

40

Percent

shorter transport times and

approx. 60 cycles/min

=

enormous dynamics

10

Kg

payload

=

wide range

of components

Process

Capability

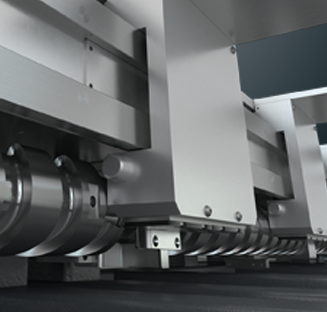

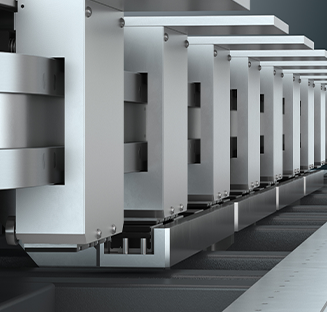

The “Hybrid” in LS Hybrid stands for a hybrid drive system, but also for “hybrid productivity”. It combines fast, precise tooling transport with the high process capability of the transfer system. No other transfer system currently offers this combination and process capability.

PRODUCTIVITY THROUGH

MODULARIZATION.

HYBRID DRIVE CONCEPTs

MADE TO SIZE.

Movement profiles can be flexibly assigned to cam drives, corners, conveyor sections or other components of the LS Hybrid transfer system. This opens up entirely new prospects for production.

FREELY COMBINABLE ELEMENTS.

MODULARITY FOR OPTIMIZED USE.

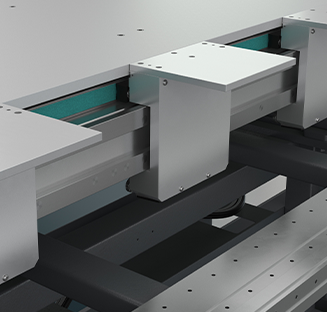

Drive Technology

eCAM MODULe

- Total locking without additional indexing

- Maximum precision

- Extremely fast transfers

- Infinitely connectable without the need for intermediate conveyors

- Low maintenance

Drive Technology

Linear motor Module

- Processes can be uncoupled in time

- Freely definable stop position

- Forward and backward motion

- Variable speeds with high dynamics

- Entire preprogrammed sequences available; also freely programmable

Drive Technology

belt MODULe

- Intelligent decoupling of different strokes

- Controlled transfers between process stations

- Available as single or double belt

- The parts of the latter can run at different speeds over the trajectory

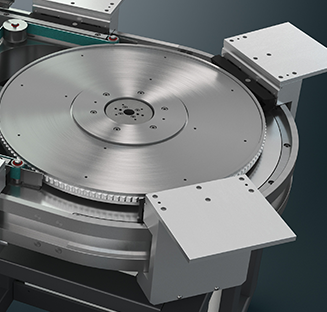

Drive Technology

Corner Module

- Freely programmable rotary table

- Can also be positioned in a curve, e.g. for loading and unloading

- Reduces required space for production

- Positioning Accuracy of ±0.15 mm (optional feature)